PCM/TPM is expected to become the mainstream solution for thermal interface materials in intelligent driving

Heat dissipation challenges of intelligent driving domain control

The thermal management issue of intelligent driving domain control is becoming one of the key topics that must be overcome in the process of intelligent upgrading of automobiles.

NO.1 The soaring power density and higher integration have accelerated the demand for high thermal conductivity materials

To ensure the heat dissipation effect and system reliability, the thermal conductivity is undoubtedly important, but the system's thermal resistance is the key factor determining the actual heat conduction efficiency. Thermal resistance is influenced by multiple factors such as material thickness, contact area, and compression characteristics. Only by optimizing these key variables can the actual thermal resistance of the system be minimized and long-term reliability be guaranteed.

NO.2 Complex working conditions impose more stringent requirements on reliability

The intelligent driving domain controller needs to operate stably for a long time under complex conditions such as high and low temperatures and vibration. The base material selection, formula design and other aspects have been comprehensively upgraded. This includes the fact that after thermal shock, traditional thermal conductive adhesives can cause chip warping and form gaps with the adhesives, leading to thermal failure, while traditional thermal conductive silicone grease is prone to risks such as pump-out and dry-out.

NO.3 The upgraded thermal conductive material poses higher requirements for process adaptability

In terms of process realization, high-performance thermal conductive materials are needed to adapt to the "synergistic challenge" of efficient production and convenient assembly.

PCM/TPM is expected to become the mainstream solution for thermal interface materials in intelligent driving

Techinno phase change material Fill-PCM 800

1. Outstanding performance

After the phase transformation of FF-PCM 800, an extremely low BLT can be achieved with only low pressure. The thinner BLT can significantly reduce the interfacial thermal resistance, which enables this material to achieve excellent low thermal resistance performance under low pressure conditions.

2. Strong reliability

In response to the harsh usage environment of automotive electronics, FF-PCM 800 has passed multiple reliability verifications: after undergoing continuous high-temperature, high and low temperature shock, and double 85 tests, no thermal conductivity attenuation was observed. And there is no risk of extrusion, cracking or sliding down after long-term use. Anti-vibration and anti-shock, suitable for vehicle-mounted working conditions.

Compared with traditional silicone grease, Fill-PCM800 has better resistance to pump-out. After 1000 cold and hot cycle tests ranging from -40℃ to 125℃, Fill-PCM800 showed no obvious pump out phenomenon.

3. Excellent adaptability

The Fill-PCM 800 adopts a customized design, offering various forms such as rolls, sheets, and customized shapes. It also has its own adhesive property, enabling rapid and precise assembly. In addition, we have launched a paste printable version of the same series, FF-PCM 800SP, further expanding the flexibility of adaptation to automated process flows.

Ultra-thin thermal interface material Fill -TPM 800

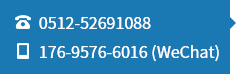

1.Anti-sagging performance

The Fill-TPM800 maintained a stable shape without sagging during the testing process. Even in the more stringent high-temperature durability test environment, it still demonstrated excellent stability and was less likely to encounter problems over long-term use. Its excellent anti-sagging performance can meet the strict requirements for material stability in fields such as automotive electronics.

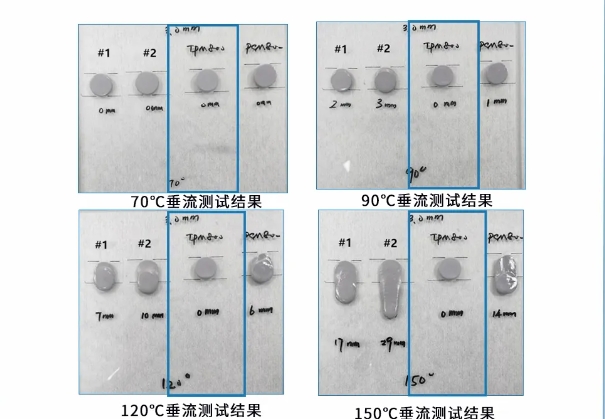

2. Anti-pumping performance

Ff-tpm 800 has a higher cohesion and demonstrates stable and excellent anti-pumping capability in vibration cycles within the 70-120μm range, nearly stably controlling thermal resistance. This stable thermal resistance control is particularly important for demanding application scenarios like intelligent driving domain control.

3. Vibration and shock resistant

Ff-tpm 800 has been verified through special mechanical tests. In the vibration test, no obvious displacement or cracking was observed in the material. Under a wide temperature range and a certain vibration intensity, its structural stability is good. Under the mechanical shock test, no obvious displacement cracking was observed in the material either. The FF-TPM 800 can withstand strong mechanical shock and has high reliability.

Techinno Fill-TPM 800, with its triple core advantages of "extreme temperature resistance, long service life stability, and resistance to chemical stress", perfectly ADAPTS to the harsh usage environment of automotive electronics, providing stable heat dissipation guarantees for the long-term reliable operation of on-board devices. It is the preferred solution for thermal conductive materials in intelligent driving domain control.

For the automotive industry, only thermal interface materials that balance heat dissipation performance, high reliability, assembly convenience and mass production efficiency can become the "heat dissipation cornerstone" of domain controllers. The Tegino series of materials, with their strong capabilities in meeting multi-dimensional demands, not only lay a solid foundation for heat dissipation for domain controllers but also serve as reliable heat dissipation partners in the process of large-scale application of smart vehicles.