Thermal Conductivity Solutions for UAVs

Techinno Solution:Fill-Gel 1000

Thermally conductive interface materials for UAVs should have low density, low volatility, vibration resistance and easy handling. Considering the ease of production process and the management cost of large-scale production, Techinno recommends Fill-Gel 1000 as the solution.

Features

Thermal Conductivity: 10.0W/m-K

High reliability and thermal stability

Low volatiles and siloxane content

High compressibility for low stress applications

Low contact resistance

No pump-out, no crack/slide at thermal cycling and vibration environment

Typical Applications

Chassis or the associated cooling module

Heating with low assembly pressure

Smart terminals, mobile phone, tablet computer

Telecommunication base station

Large storage data center

Memory & Power Modules

Detailed Explanation of Materials

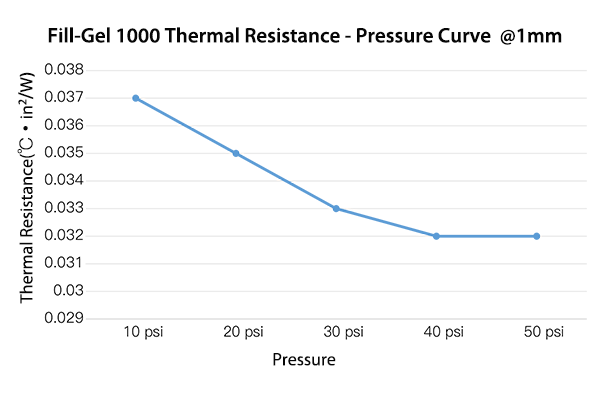

Thermal properties of Fill-Gel 1000

Techinno Fill-Gel 1000 has good thermal properties, with good thermal resistance under low pressure, high thixotropy, high deformation at low pressure, and large tolerance interfaces to fill the interface gaps, avoiding localized temperature differences in components caused by uneven thermal conductivity.

Flow Rate Test of Fill-Gel 1000

The unique formulation design allows Fill-Gel 1000 to achieve an actual flow rate of 23g/min (30cEFD tube, 2.5mm orifice diameter 90psi60s) with good long term reliability.

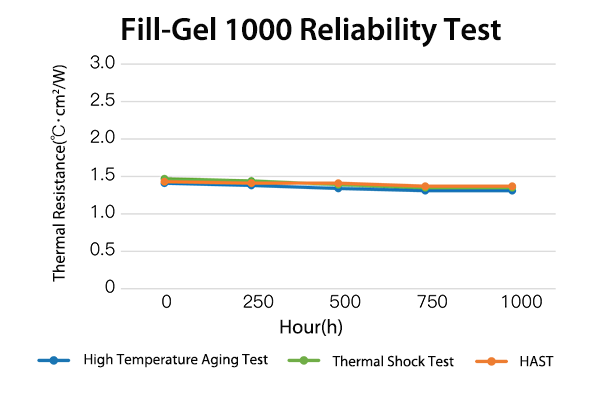

Reliability of Fill-Gel 1000

Fill-Gel 1000 has a stable thermal resistance throughout the aging test.Fill-Gel 1000 has stable thermal resistance performance throughout the reliability test. Under the high temperature aging test, thermal shock test and HAST,Fill-Gel 1000 can maintain its initial thermal performance without any sign of thermal conductivity decline.