LIDAR Thermal Conductivity Solution

Techinno Solution:Fill-Gel600LV

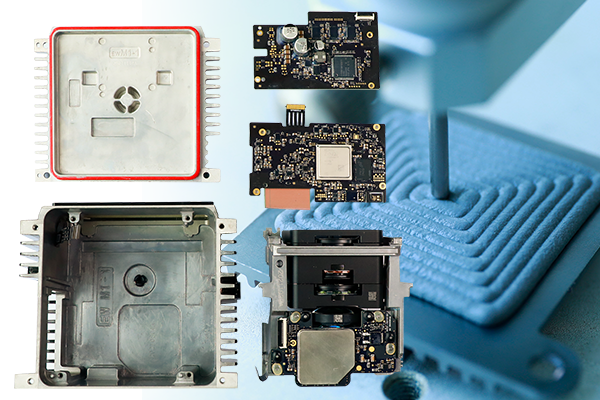

Lidar requires thermally conductive materials with high thermal conductivity, low volatility and vibration resistance. Considering the convenience of the production process and the cost of material management, Techinno recommends the one-component thermally conductive gel Fill-Gel 600LV as a solution.

Feature

Thermal Conductivity: 6.0W/m-K

High reliability and thermal stability

No post cure, easily for auto-dispensing

Low volatility,High compressibility for low stress applications

Low contact resistance

No pump-out, no crack/slide at thermal cycling and vibration environment

Typical Applications

Chassis or related cooling modules

LED lighting

Intelligent terminals, cell phones, tablet PCs

Communication equipment, optical modules

Hard Disk Drives and Solid State Drives (SSD)

Camera Modules

Detailed Explanation of Materials

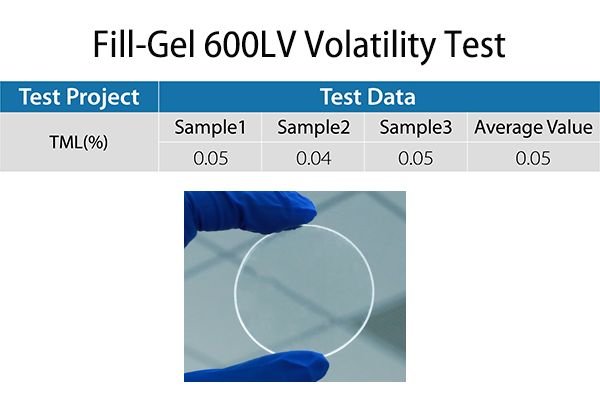

Volatility test of Fill-Gel 600LV

Fill-Gel 600LV has a silicone content of <100PPM and a measured total volatile matter content as low as 0.05% after 24H 125°C vacuum baking.

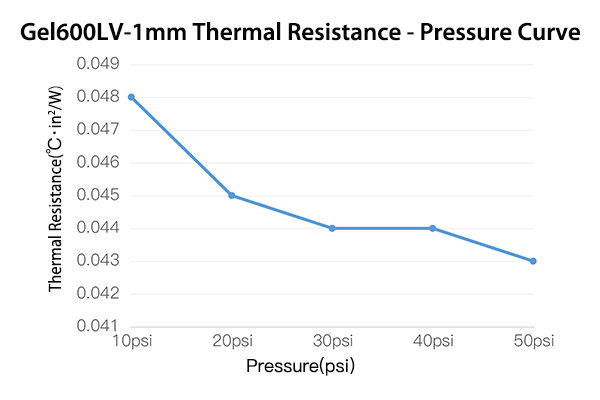

Thermal Performance of Fill-Gel 600LV

With a thermal conductivity of 6.0W/m-K, Fill-Gel 600LV's thermal resistance is able to remain stable in low-pressure, high-tolerance environments, enabling rapid heat transfer.

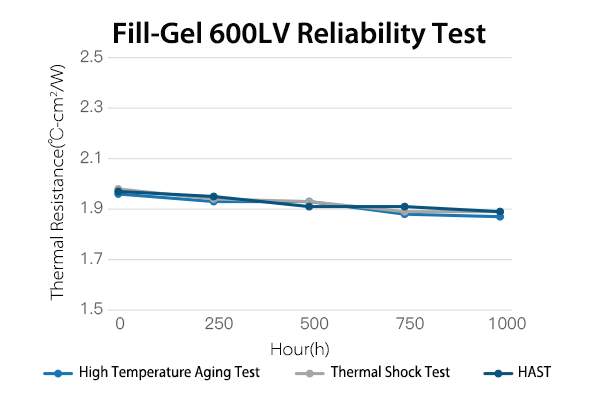

Reliability of Fill-Gel600LV

Fill-Gel600LV has a stable thermal resistance throughout the aging test.Fill-Gel600LV has stable thermal resistance performance throughout the reliability test. Under the high temperature aging test, thermal shock test and HAST,Fill-Gel600LV can maintain its initial thermal performance without any sign of thermal conductivity decline.