Laser Thermal Conductivity Solution

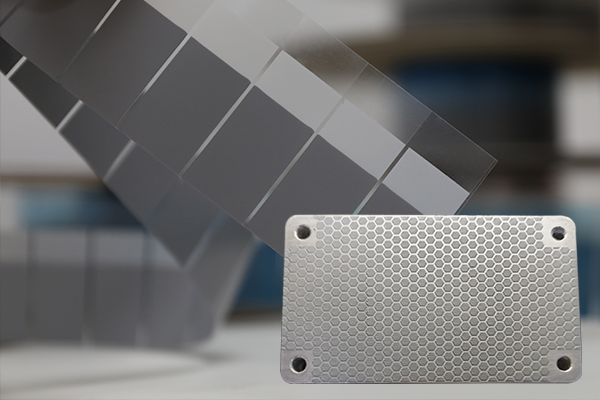

Techinno Solution:Fill-PCM 550SP

Fill-PCM 550SP has high thermal conductivity and low viscosity, which makes it easy to construct and dissipate heat from the pump source.

Feature

High thermal conductivity and extremely low thermal resistance

Silicone free, no silicone contamination

Natural tacky, stick on the surface of heat sink directly, no additional adhesive

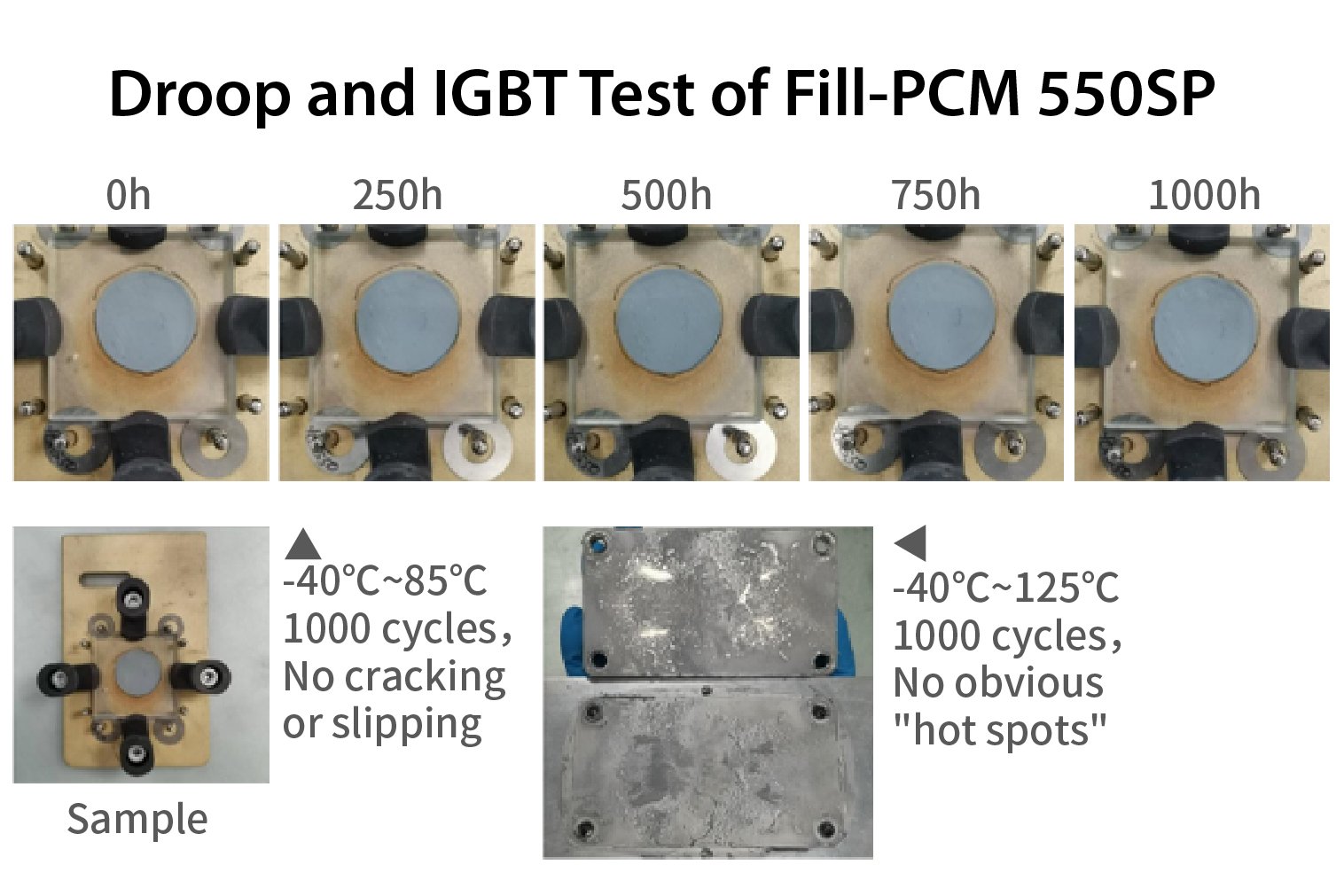

High reliability, no pump out/dry out/crack/slump in long term application

Good handling and reworkability

Soft at room temperature, less stress on board during assembly

Typical Applications

Laser Pump Sources

Notebooks, Desktops

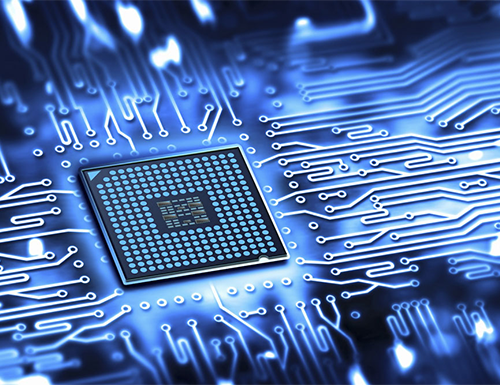

Graphic processing chips

Memory Modules

Consumer electronics such as TVs, game consoles, etc.

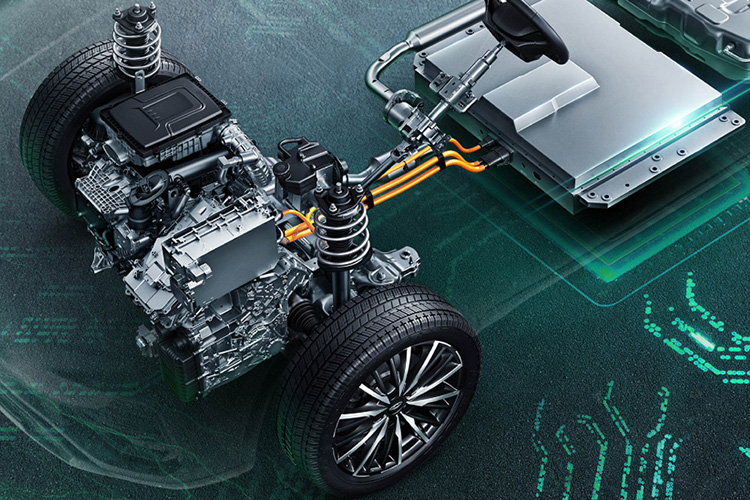

Automotive

Detailed Explanation of Materials

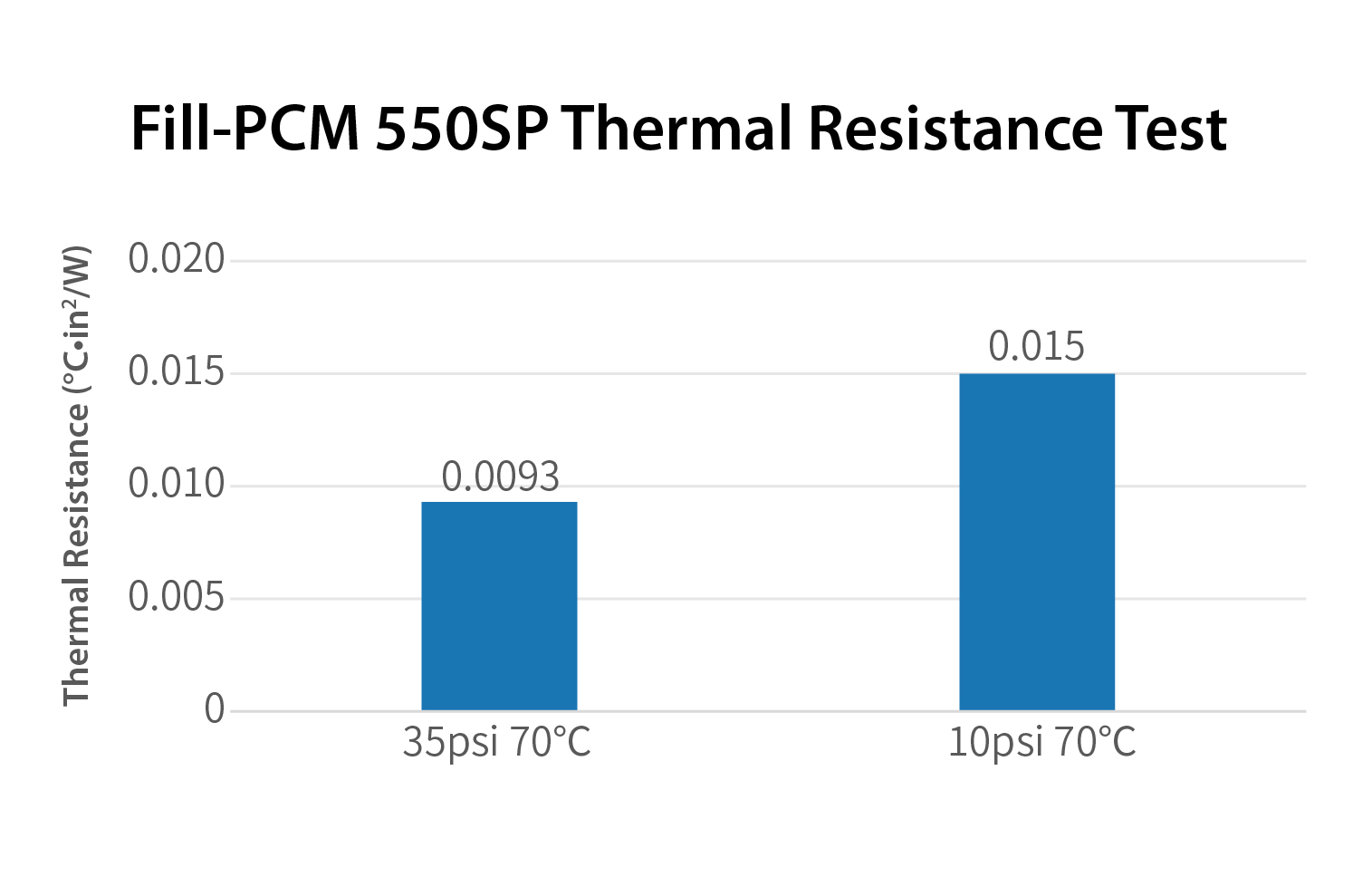

Thermal Performance of Fill-PCM 550SP

Fill-PCM 550SP has a very low viscosity in the molten state, so low BLT can be achieved very quickly at very low pressures, and the very low BLT brings lower thermal resistance, so Fill-PCM 550SP can achieve low thermal resistance at low pressures, and improve the efficiency of thermal conductivity.

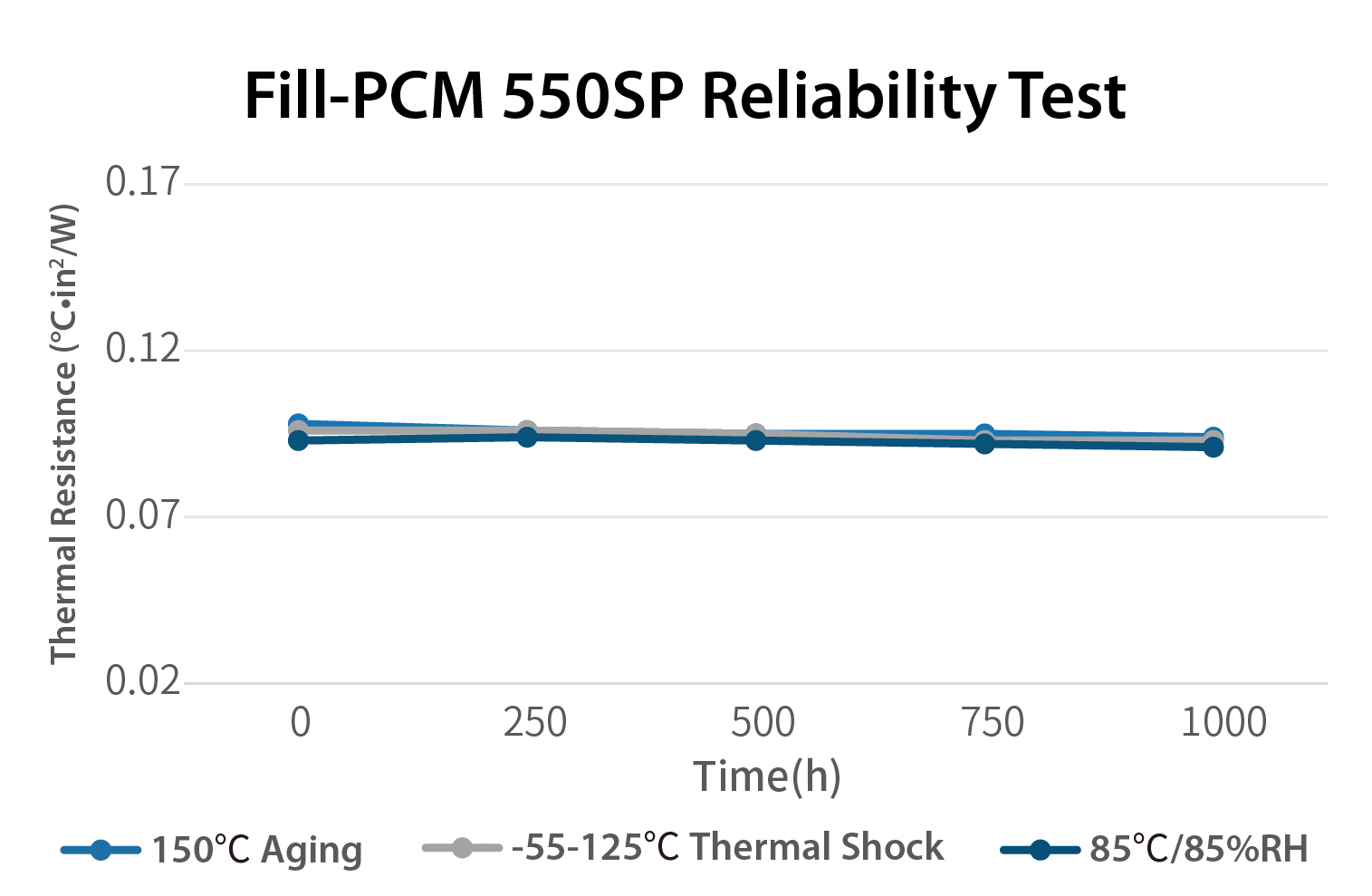

Reliability of Fill-PCM 550SP

Fill-PCM 550SP has a stable thermal resistance throughout the aging test. Fill-PCM 550SP has stable thermal resistance performance throughout the reliability test. Under the high temperature aging test, thermal shock test and HAST, Fill-PCM 550SP can maintain its initial thermal performance without any sign of thermal conductivity decline.